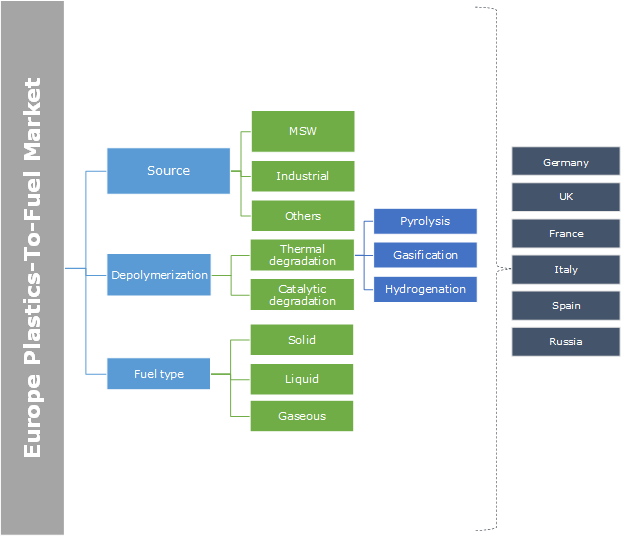

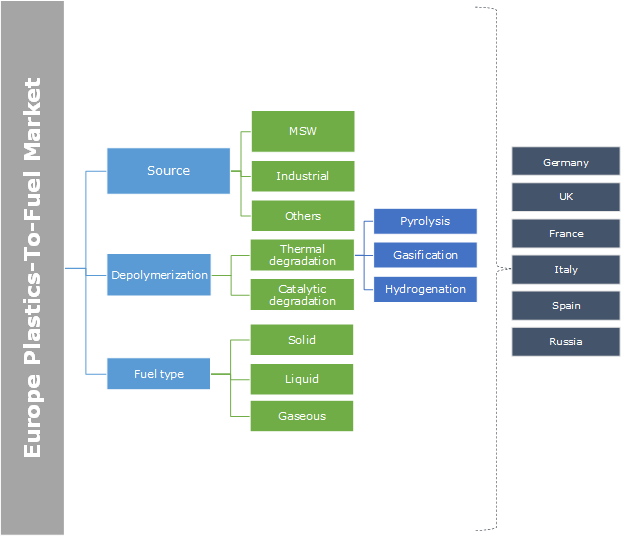

According to the Graphical Research new growth forecast report titled “Europe Plastics-To-Fuels (PTF) Market Size, By Source (Municipal Solid Waste (MSW), Industrial), By Depolymerization (Thermal Degradation [Pyrolysis, Gasification, Hydrogenation], Catalytic Degradation), By Fuel Type (Solid, Liquid, Gaseous), Industry Analysis Report, Country Outlook, Application Potential, Price Trend, Competitive Market Share & Forecast, 2020 – 2026” to Witness Steady Growth by 2026.

The emergence of new plastic-to-fuel technologies will augment Europe plastics-to-fuels market expansion. Rising awareness of environmental damage caused by single-use plastics is compelling researchers to find out new ways of proper plastic waste disposal. Many scientists have been examining plastics as an alternative source for fuel production for a long time and to harness its fuel content. Currently, many technologies have been developed to convert non-recycled plastics into fuels, industrial feedstocks, and crude oil. Plastic-to-fuel technologies can be customized depending on requirements. Furthermore, these technologies can produce a cleaner-burning fuel owing to low sulfur content of plastics. Such eco-friendly benefits of plastic-to-fuel technologies will drive Europe plastics-to-fuels market growth in the future.

In January 2018, the European Commission adopted an initiative the “European Strategy for Plastics in a Circular Economy”. This strategy will help Europe to attain sustainable development goals, protect the environment, and minimize greenhouse gas emissions. Furthermore, this strategy will boost plastic recycling activities and pave way for plastic-to-fuel producers. The temporary coronavirus crisis will adversely affect market growth for a short-term. Due to strict lockdown measures and transportation bans, production units have been stopped and supply chains have been hampered in a significant manner. However, Europe plastics-to-fuels market growth will gain momentum as the situation normalizes.

Plastics-to-fuel processes are extremely costly, energy-sensitive, and requires proper infrastructure. Pyrolysis process, one of the most popular processes used for plastic-to-fuel conversion, requires USD 7,080 to USD 10,600 for the production of 1 kilowatt of energy. The waste feedstock needed for pyrolysis requires pre-treatment in the form of drying and shredding, that consumes a significant amount of energy. In addition, the whole business unit set up requires proper collection, sorting, and processing infrastructure, thereby needing a significant capital investment. Another disadvantage of fuels derived from plastic wastes is their low flashpoints as it can create unnecessary implications during transportation. Many manufacturers are trying to find cost-effective processes for plastic-to-fuel production, which will aid in minimizing overall production costs.

The Europe plastics-to-fuels market by source is segmented into municipal solid waste, industrial waste, and others including medical waste, e-waste, etc. The others segment will cross USD 245 million by the end of the forecast period. The thermal degradation segment will account for over 90% share by the end of the forecast period. In a pyrolysis process, a variety of plastic materials are heated in a controlled manner in the absence of oxygen. A plastic macromolecular structure is broken into smaller molecules by heating. The gaseous fuel segment will account for approximately 11% share until the end of the forecast period.

The key players in the Europe plastics-to-fuels industry are Neste, Quantafuel, and Greenfuels AG. These manufacturers are expanding production capacity, investing in research & development activities, and modernizing production infrastructure to gain a competitive edge.