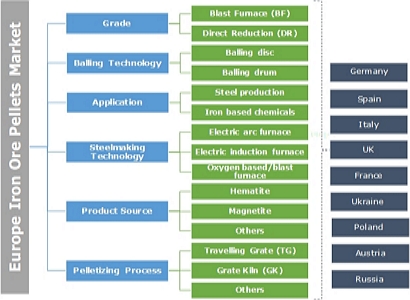

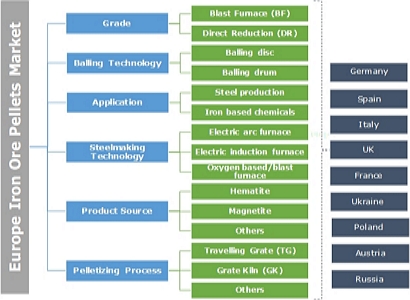

According to the Graphical Research new growth forecast report titled “Europe Iron Ore Pellets Market Size, By Grade (Blast Furnace, Direct Reduction), By Balling Technology (Balling Disc, Balling Drum), By Application (Steel Production, Iron-based Chemicals), By Steelmaking Technology (Electric Arc Furnace, Electric Induction Furnace, Oxygen-based/Blast Furnace), By Product Source (Hematite, Magnetite), By Pelletizing Process (Travelling Grate, Grate Kiln), Industry Analysis Report, Country Outlook, Application Potential, Price Trend, Competitive Market Share & Forecast, 2020 – 2026”, to Witness Vast Growth by 2026

Europe is one of the largest consumers of iron ore pellets across the globe. The market is home to major industries such as automotive, industries, and construction. The attempt of European countries to improve industrial competitiveness by introducing modernized digital initiatives such as Industry 4.0 is expected to improve the region’s overall competitiveness in the iron and steel commodity market. Europe in terms of strategic interest is also encouraging efficient domestic core utilization through the introduction of strategic import tariffs on some steel products. After the introduction of a 25% tariff on selected 23 imported steel product categories in mid-2018, the region reported a positive impact on continuous cast steel output in 2018.

Currently, COVID-19 pandemic is impacting the already slowing down the European steel industry, which is going through a demand slump since 2019 owing to geopolitical uncertainties, such as Brexit. To tackle these issues, regional governments have proposed several relief packages in the end-user industry, such as automobiles, to promote demand and rebound demand for iron ore pellets.

DR grade pellets will witness over 4% CAGR in Europe iron ore pellets market size owing to the growing need for high-grade iron ores in the steelmaking industry. These products generate low carbon emissions and utilize disintegration property to retain a high amount of iron content. In terms of balling technologies is segregated into balling disc and balling drum.

Iron ore pellets find a wide range of applications in major industries including steel production and in iron-based chemicals, among others. Iron-based chemicals will witness over 2.5% CAGR in market and is credited to the increasing usage of such chemicals for water treatment as coagulants. The rising focus of regulatory bodies to improve water quality is also a contributory factor in the segment growth.

The electric induction furnace will showcase significant growth owing to its capability to attain higher yields coupled with clean burning and higher melting rates. Magnetite segment holds around 60% share in Europe iron ore pellets market size owing to presence of large reserves. Further, rising demand for steel are offering potential growth opportunities for industry participants for developing magnetite deposits.

Based on the pelletizing process, the Europe iron ore pellets industry is segmented into travelling grate, grate kiln, and others. Others segment include shaft furnace, cold bonded palletization process, etc. and accounts for a significant share. The shaft furnace pelletizing process is traditionally used in many facilities across Europe.

Industry participants are expanding their portfolio of pelletized products to gain an influence in the industry. In July 2020, Michaelovsky GOK, a major Russian iron ore miner and processor, announced the pilot production of premium-grade iron ore pellets with high purity iron and low polluting elements, meeting global market requirements. Major manufacturers in the Europe iron ore pellets marketplace include LKAB, Nordic Iron Ore, FERREXPO, Arcelor Mittal, and several others.