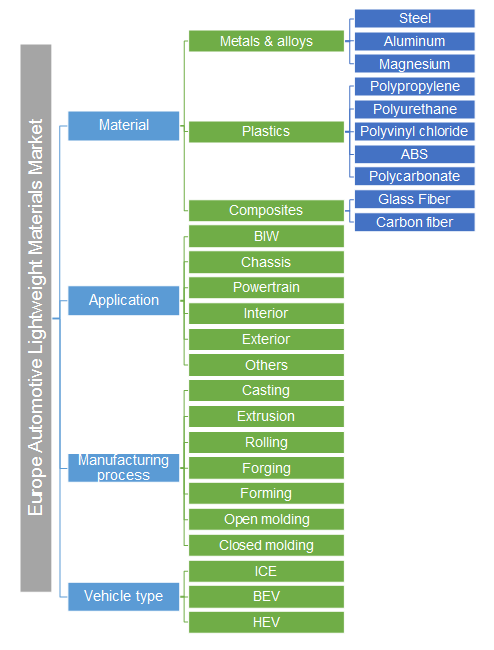

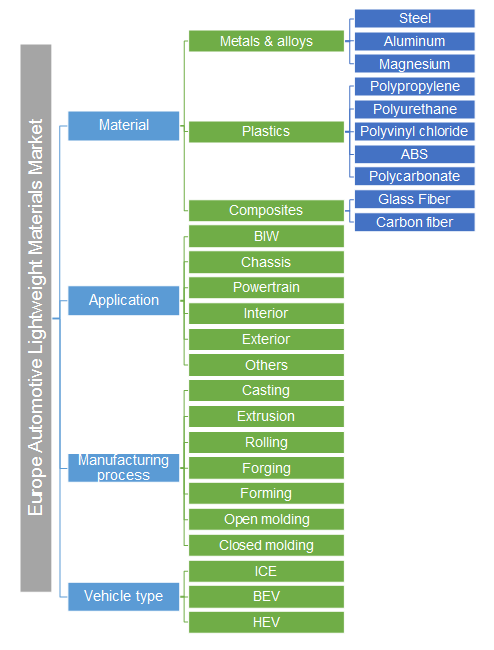

According to the Graphical Research new growth forecast report titled “Europe Automotive Lightweight Materials Market Size By Material (Metals & Alloys [High Strength Steel, Aluminum, Magnesium], Plastics [ Polypropylene, Polyurethane, Polyvinyl Chloride, ABS, Polycarbonate], Composites [Glass Fiber, Carbon Fiber]), By Application (Body In White, Chassis, Powertrain, Interior, Exterior), By Manufacturing Process (Casting, Extrusion, Rolling, Forging, Forming, Open Molding, Closed Molding), By Vehicle Type (Internal Combustion Engine Vehicle, Battery Electric Vehicle, Hybrid Electric Vehicle), Industry Analysis Report, Regional Outlook, Growth Potential, Price Trends, Competitive Market Share & Forecast, 2020 – 2026” to witness steady growth by 2026

Road transport sector in Europe is under increasing pressure to reduce its greenhouse gas emission which has reached closed to 0.8 gigaton CO2eq, 18% of the total greenhouse gas emission in 2017. Various nations in Europe are working on meeting decarbonization targets set by European Commission. Automobile industry in Europe is currently following two different approaches; improving fuel efficiency of automotive and finding alternative energy sources. Both these parameters benefit immensely from reduction of vehicle weight, this will increase distance travelled by the vehicle per unit of energy.

Europe is a huge car manufacturing hub which is also becoming a hub for automotive lightweighting. European market for lightweight automotive is primarily driven by developments and initiatives with the European Union which is driven by technological development as well as regulatory framework. The move towards achieving competitive low-carbon economy by 2050 is anticipated to pull other nations in this direction. Automotive manufacturers and suppliers are continuously investing in developing new and advanced materials, thereby driving Europe automotive lightweight materials market growth.

Composite will witness over 7.5% CAGR in Europe automotive lightweight materials market owing to its strength, fatigue resistance, flex, shear strength, rigidity and heat resistance. In the automotive industry plastic car parts have achieved this strength by incorporating glass fibers or carbon fiber with molten plastics. Various composite fiber mainly carbon and glass will aid automotive industry with developing more flexible and durable lightweight materials.

Closed molding process will witness significant growth as it reduces automotive part production cycle-time. This manufacturing process is time and cost efficient and generates fewer toxic gases. Recently, the U.S. national research lab produced new polymer composites using longer as well as high strength glass fibers along with Moldflow CAD software. Industries are now investigating different carbon composite to reliably predict the part performance in high speed closed molding.

Battery electric vehicles is projected to grow at around 32% CAGR in Europe automotive lightweight materials market till 2026. The region is rapidly becoming a global hotspot for electric vehicles market owing to numerous incentives introduced by various national governments driving the industry for the projected time period.

Europe automotive lightweight materials market is predominantly driven by Germany, France and U.K. Germany will witness over 9.5% CAGR in terms of revenue by 2026. Germany has employed several carrot and stick policies specially designed to increase electric vehicles demand. For instance, value added tax on electric vehicles fall from 19% to 16% during July to December 2020. Any privately owned electric vehicles registered till the end of 2020 will have a 10-year tax exemption. Moreover, electric vehicles with a sale price below USD 49,000 will qualify for a USD 10,000 subsidy till the end of December 2021.

Major participant in the Europe automotive lightweight industry include British steel, ArcelorMittal, Creusot-Lorie, Lyondellbasell, BASF, Covestro AG, Thyssenkrupp AG., etc.