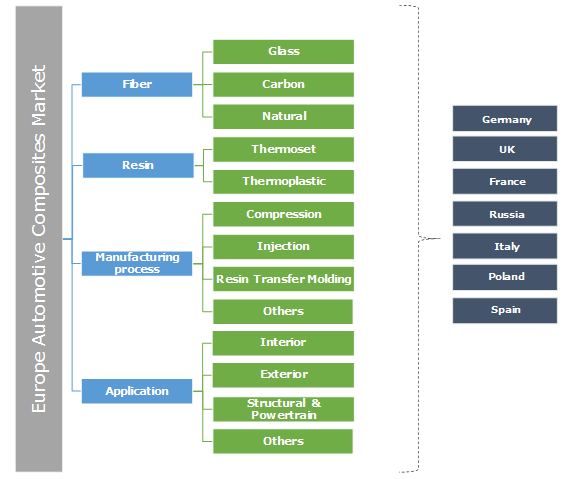

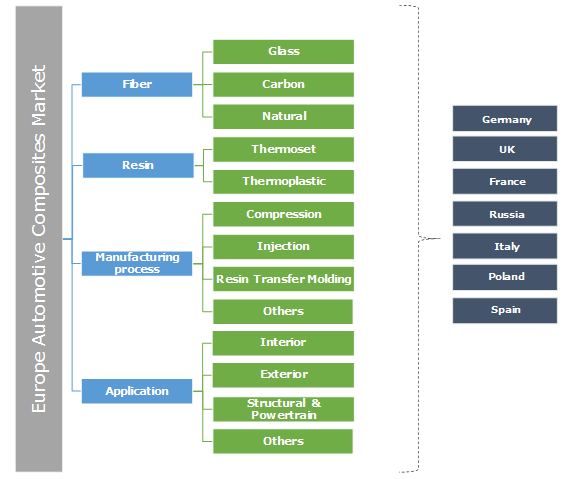

According To Graphical Research, The New Growth Forecast Report Titled “Europe Automotive Composites Market Size, By Fiber (Glass, Carbon, Natural), By Resin (Thermosetting, Thermoplastic), By Manufacturing Process (Compression, Injection, Resin Transfer Molding), By Application (Interior, Exterior, Structural & Powertrain) Industry Analysis Report, Regional Outlook, Growth Potential, Price Trends, Competitive Market Share & Forecast, 2020 – 2026” To Witness Strong Growth By 2026

The Europe automotive composites market is mainly driven by the strong automotive industry base in the region. Strict emission regulations and manufacturing standards on the reduction of greenhouse gas emissions will propel the demand for lightweight composites. These composites will find applications majorly in interior and exterior automotive body parts to provide high strength at low weight. The EU and other regulatory bodies in the region are focusing on reducing CO2 emissions up to 95 g per km with the incorporation of lightweight materials including, carbon, and natural fibers. Extensive usage of composites in luxury vehicles, sports cars, and buses will substantially augment the Europe automotive composites market growth.

Technological development initiatives in the regional automotive industry will significantly contribute to revenue generation. Automotive composites find usage in wheels & brakes, structural components, and suspension & clutch due to the soaring demand for these strong & lightweight materials. Additionally, high investments from industry participants to increase their manufacturing capacity will positively influence Europe automotive composites industry growth. In October 2018, Hexcel Corporation inaugurated its production facility to manufacture carbon fiber composites in France.

In Europe, the natural fibers segment is projected to witness over 8% CAGR in Europe market size. The regional automotive sector is witnessing a radical shift from glass fibers to natural fibers on account of its lesser density, primarily spurring the automotive composites market growth. In addition, they are relatively cheaper than glass, further influencing their consumption.

Based on resin, thermoplastic resins are gaining popularity compared to thermosetting resins and are likely to register the highest growth rate. High impact resistance of thermoplastic compared to its counterparts along with rapid molding and easy recyclability characteristics will boost the segment growth.

The injection manufacturing process is estimated to grow at a robust growth rate by 2026. This process offers excellent properties on exposure to severe temperatures. Furthermore, it is considered to be a cost-effective solution for large-scale molding projects. Lesser energy usage and floor space requirements will significantly contribute to the market growth.

The interior application is one of the key applications of automotive composites. High revenue generation can be attributed to the extensive adoption of glass and natural fibers for interior auto components. The vehicle interior applications include trims, instrument panels, windows, and seats. The replacement of steel parts with composite will further strengthen industry penetration.

The Europe automotive composites market is majorly governed by Germany, France, the UK, and Spain. Germany is the leading consumer of automotive composites in the region owing to high vehicle production across the country and the production of composites. The Russian government supports local composites producers to design innovative composites apart from the expansion of their supplies. In Italy, various auto-part manufacturers focus on manufacturing all-composite body parts and frames for their customers, proliferating product consumption in the country. The industry participants include Koninklijke Ten Cate, SGL Group, Polar Manufacturing, Scott Bader, Gurit Holdings AG, and Cytec Solvay Group.