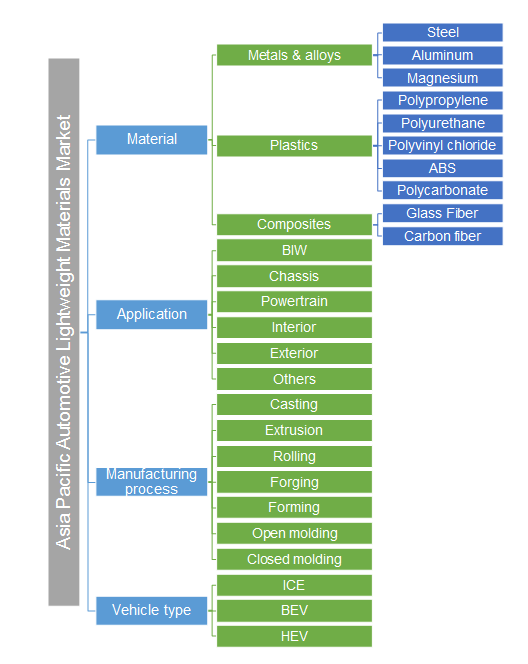

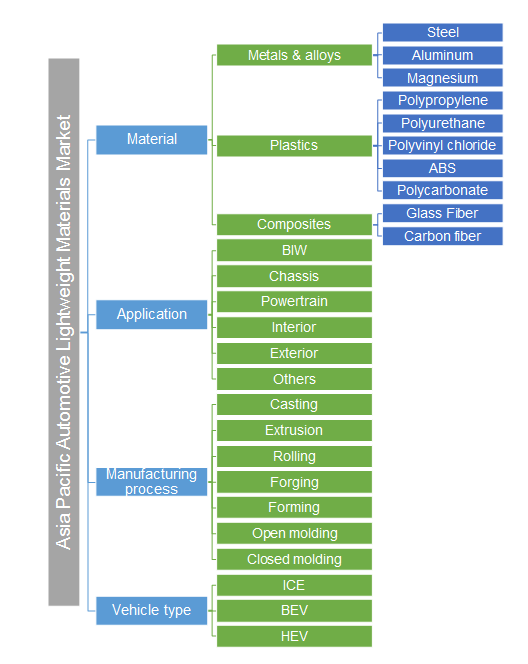

According to the Graphical Research new growth forecast report titled “APAC Automotive Lightweight Materials Market Size By Material (Metals & Alloys [High Strength Steel, Aluminum, Magnesium], Plastics [Polypropylene, Polyurethane, Polyvinyl Chloride, ABS, Polycarbonate], Composites [Glass Fiber, Carbon Fiber]), By Application (Body In White, Chassis, Powertrain, Interior, Exterior), By Manufacturing Process (Casting, Extrusion, Rolling, Forging, Forming, Open Molding, Closed Molding), By Vehicle Type (Internal Combustion Engine Vehicle, Battery Electric Vehicle, Hybrid Electric Vehicle), Industry Analysis Report, Regional Outlook, Growth Potential, Price Trends, Competitive Market Share & Forecast, 2020 – 2026” to witness steady growth by 2026

The APAC automotive lightweight materials market is driven by the rising investments for developing lightweight and cost efficient automotive. The growing need for reducing overall weight of automobile can be attributed towards minimizing fuel consumption per liter. Consumer awareness regarding lowering CO2 and other greenhouse emission has surged the need for developing hybrid and electric vehicles. Moreover, rising inflow of foreign investments in the region will positively contribute towards industry expansion.

The APAC automotive lightweight materials market is also witnessing rapid demand from the growing automotive sector in terms of domestic production and sales. The region accounts for major automotive production and is also experiencing a rapid rise in capacity expansion from major automotive players such as Volkswagen, Tesla, Hyundai, Tata Motor, General Motors, etc.

Aluminum remains the most the important raw material required to produce lightweight materials due to its lower cost and easy availability. Aluminum can help reduce the weight of automotive components by more than 50% as compared to cast iron on stainless steel. Growing penetration of electric vehicles across the region will further drive the APAC automotive lightweight materials market growth.

Growing competition in the automobile industry requires application of low-cost production which is interlinked with lightweight manufacturing. The growing need for lightweight manufacturing in automotive industry is supported by various reasons like stringent and increasing environment restrictions, the need for reducing toxic emission and higher safety requirements. To fulfill these requirements, weight reduction of automotive is important. In the overall weight of an automobile, automotive body plays a decisive role. Metal forming is considered as an important manufacturing process in production of car body. Therefore, development of new technique in metal forming is necessary for production of lightweight materials.

Battery electric vehicles are anticipated to grow at 22.9% CAGR in APAC automotive lightweight materials market till 2026. This can be attributed to rising demand for lowering fuel emission and following air quality standards which primarily contribute towards propelling the segment share. Rising income level coupled with tax exemption for electric vehicles will further boost the Asia Pacific automotive lightweight materials industry.

Asia automotive lightweight materials market is predominantly driven by China, Japan, India and South Korea. India will witness around 8.7% CAGR in terms of revenue till 2026. The country boasts the presence of many production facilities for hybrid and electric vehicles. The positive economic reforms to grow automotive industry coupled with fast growing economic conditions have propelled the demand for lightweight materials.

Market participants in the industry include Tata steel, posco, Luneng Jinbei, Saint Enterprise, Ace global, Shandong Xinfa Aluminum group and Hangzhou Jinjiang group.